Gear Solutions

We are a leading gear manufacturer that provides products with high reliability and durability leveraging

our precise design technology and a variety of analysis, verification, and testing procedures.

- Industrial Machinery

- Gear Solutions

- Special Gear Units

Special Gear Units

Hyosung Heavy Industries ensures high product reliability by employing experienced technical development personnel and conducting various analyses, verifications, and tests.

We provide customized solutions for a wide range of applications, with a proven track record of timely delivery.

Product Classification

Discover custom solutions that meet your needs.

Wind Turbine Gear Unit

In 2005, Hyosung started developing a gear unit for wind turbines, and has since progressed to developing a 2MW gear unit after developing a gear unit in the 750kW-class. We are in the process of developing gear units with a capacity of 1.65MW and 5MW in response to increasing demand for green energy solutions.

Features

- Ease of maintenance

- High gear ratio and power density

- Application of hydraulic damper (2MW)

- Optimized design (gear, shaft, casing)

- High durability of gear adopting flexible pins (2MW)

Vertical Roller Mill Gear Unit

Hyosung's vertical roller mill gear unit is a crucial component in crushing coal, which is the main fuel for thermal power plants, as well as limestone for cement plants. The product is durable and can endure challenging conditions and heavy loads, and a temperature sensor can be attached to regulate the temperature of the bearing and oil. The gear ratio can be reduced to around 20:1 to 40:1 by combining planetary gears and bevel gears.

Features

- Power is transmitted from the horizontal input shaft to the vertical output shaft through a combination of bevel and planetary gears

- Designed with a sturdy exterior that can withstand heavy loads

- Bearings are used to support the vertical load force of the top grinding machine

- By implementing a precise lubrication system and hydraulic control to maintain cleanliness, we have reduced the friction loss of gears and extended the lifespan of bearings. This ensures thorough gear lubrication and oil management, resulting in a longer lifespan for the reducer

Jacking System

Hyosung's jacking system is designed to support the weight of jack-up vessels during installation and relocation. It provides support for the legs of the vessel when it is stationary on the water and during relocation. The typical setup involves connecting 36, 54, or 72 gear units to one vessel, which is designed to distribute and drive the loads generated by each individual gear unit.

Features

- Various reduction ratios: from 100:1 to 20,000:1 or even higher

- Self-load test capability exceeding 1,200 tons

- Rapid delivery response

- Superior quality even under heavy loads with robust durability

- Obtained ABS and CCS classification certifications

- Diverse delivery performance since 2006 (440kips, 550kips, 660kips, 750kips, 1,000kips)

Steel Mill Gear Unit

Hyosung's steel mill gear units have achieved multiple certifications and accomplishments, such as being used in the edger for cutting steel plate, coiler for thin plate, 2-speed steel material transfer, leveler for rolling, mill for grinding raw materials, and more, demonstrating the high quality and reliability of our gear units, which have earned the trust of customers.

Features

- Forced lubrication method applied

- Mandrel shaft applied (coiler)

- Easy maintenance with bush applied (coiler)

- Multi-axis and more than 2 input powers provided (leveler)

- Gear transmission using a hydraulic system (2-step shifting)

Marine Gear Unit

Hyosung's marine gear units are designed to be used in harsh operating conditions such as on ships and include several types of reducers, such as the main propulsion gearbox, thruster gearbox, dredger pump gearbox, and generator gearbox. Advanced and complex technology is essential in the design and production stages of marine gear units as they demand greater reliability and durability compared to other types of reducers. Especially for large ships, the propulsion reducer necessitates extensive processing during both design and production stages as it cannot be replaced over the ship's lifetime.

Features

- Optimal design for various customers

- Infrastructure ensuring rapid delivery and excellent quality

- Simple operation and maintenance

- Product reliability and durability ensured

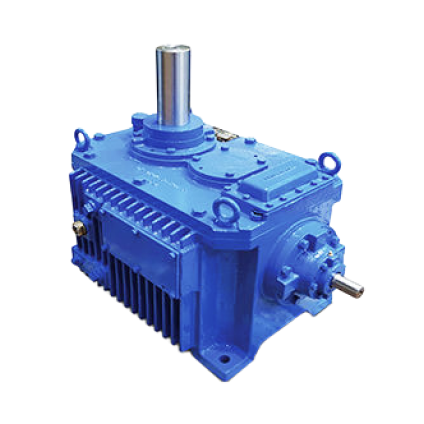

Cooling Tower Gear Unit

The cooling tower gear unit is responsible for the rotation of the blades installed on the cooling tower, and it needs to be both durable and water-resistant, even when used for extended periods. To achieve the rotation of the vertical shaft, the input and output shafts are arranged perpendicularly, while considering the customer's specifications and requirements during the design process.

Features

- IP55 or higher IP rating

- Axis in vertical upward direction

- Perpendicularly arranged input and output shafts

- Use of bevel gears

References

Our track records speak for ourselves.

-

Republic of Korea

Wind turbine, 750kW

- [Gearbox Specification]

- - Gear Ratio : i = 75

- - Weight / Configuration : 6,000kg / 1 Planet + 2 Parallel

-

Republic of Korea

Wind turbine, 2,000kW

- [Gearbox Specification]

- - Gear Ratio : i = 125

- - Weight / Configuration : 16,500kg / 2 Planet + 1 Parallel

-

Republic of Korea

Driving Gear Unit, 170kW 7,200RPM

- [Gearbox Specification]

- - Gear Ratio : i = 13.03

- - Weight / Configuration : 700kg / Helical + Spiral Bevel

-

Republic of Korea

Driving Gear Unit, 210kW 4,500RPM

- [Gearbox Specification]

- - Gear Ratio : i = 7.07 ( Gear teeth : 14/99 )

- - Configuration : Helical 1 reduction

-

Republic of Korea

Turning gear, 40kW

- [Gearbox Specification]

- - Gear Ratio : i = 75

- - Weight / Size : 3000kg / 1.5 x 2.2 x 2.5 meter

-

United States

Offshore Jack-up Rig, 440 ~ 920 kips

- [Gearbox Specification]

- - Gear Ratio : i = 6,690

- - Weight / Size : 6,000kg / 2.2 x 1.9 x 1.3 meter