Welding Solutions

We provide optimized welding solutions based on excellent quality and performance and lead the market with continuous product development.

- Power Systems

- Welding Solutions

- Robot Package Systems

Robot Package Systems

Since entering the business in 1978, we have secured related technologies through technical cooperation with Japan's Daihen and fostered growth in the markets through diversification centered on the domestic and international automobile and shipbuilding markets.

In particular, the automobile market is a quality market linked to robot automation, and Hyundai Robotics, a Korean company, and foreign companies like Yaskawa, OTC, Panasonic, Nachi, ABB and KUKA are competing in the welding field with robot packages.

Hyosung Heavy Industries has supplied arc and resistance welders to the automobile industry, primarily to automotive body manufacturers, taking up a 70% market share for arc welding machines. To further expand the market, we entered the arc robot package market in 2019 and the resistance and handling robot package markets in the following year through a strategic partnership with the Japanese company FANUC.

Applications

Discover solutions customized for multiple industries.

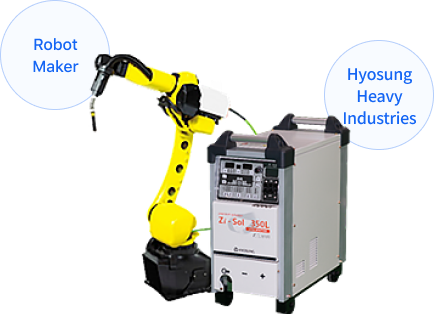

We have integrated our welding solutions into robotics.

The combination of Hyosung Heavy Industries' high-performance arc and resistance welders for FANUC's robots

cutting-edge arc and spot welding robots is the optimal welder and robot combination. It improves welding productivity and quality by

interfacing with high-performance digital communication for high-speed control of robots and welders.

-

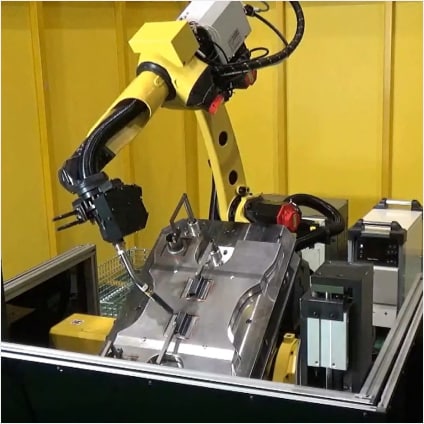

Arc Welding Robot Package

ZiSOL & ARC Mate 100iD

-

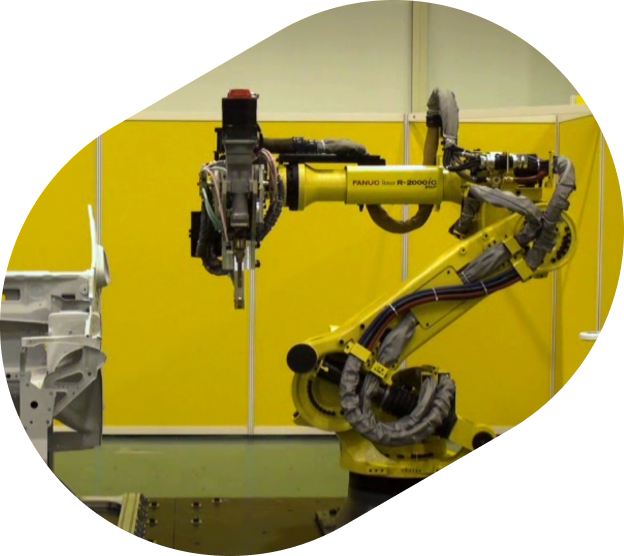

Spot Welding Robot Package

M600 & Inverter TR & R-2000iC

We consistently supply the automobile and shipbuilding industries with robot packages.

In 2019, Hyosung Heavy Industries signed a strategic agreement with Japan's FANUC, and by the end of 2022, we delivered approximately 1,000 robot packages

to automotive body manufacturers such as Sungwoo Hitech, Wooshin Industrial and shipbuilding-related companies such as Sangsangin Heavy Industries.

Currently, factories in Korea, the US, Mexico, and India are utilizing our robot packages.

Robot packages delivered(Unit: pieces)

| Classification | 2019년 | 2020년 | 2021 year | 2021 year | Total |

|---|---|---|---|---|---|

| Arc Welding Robot Package | 90 | 30 | 20 | 30 | 170 |

| Spot Welding Robot Package | - | 210 | 220 | 310 | 740 |

In addition to arc and spot welding, we are expanding into diverse robot package markets.

Although we entered the robot package market with a focus on arc and spot welding, we plan to expand into industries that use welding equipment and industrial robots in addition to the power equipment and automobile markets in the future through robot automation.

Features and Benefits

We offer specialized solutions based on superior technology.

References

Our track records speak for ourselves.

-

United States

A100 and ELCV GM Automobiles Project

- Delivered 40 sets of spot/handling robot packages

- Delivered 20 sets of arc robot packages

-

Republic of Korea

KY Hyundai Motors Project

- Delivered 10 sets of spot/handling robot packages

- Delivered 10 sets of arc robot packages

-

Mexico

BEV3 GM Automobiles Project

- M600 (TC) / Inverter TRs

- Delivered 100 units

-

Vietnam

Seojin System Manufacturing Facility Project

- Delivered 10 sets of arc robot packages

-

Russia

Zvezda Shipbuilding Yard Project

- Delivered 20 sets of arc robot packages for ship production line

-

Republic of Korea

MQ4 Hyundai Motors Project

- Delivered 20 sets of arc robot packages for automotive muffler production line

Certifications

We adhere to global standards and maintain an environment of the highest quality.

View all certifications-

NRTL(UL)

-

CE

-

CQC ZISOL

-

ISO9001

-

ISO14001

-

ISO45001