Motors & Generators

Hyosung Heavy Industries, the No. 1 producer of electric motors in Korea,

is leading the global market for key products for industrial equipment.

- Industrial Machinery

- Motors & Generators

- High Voltage Motors

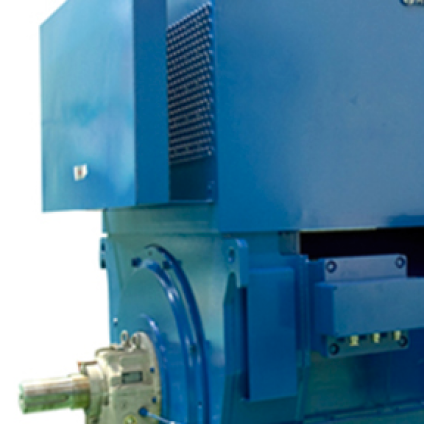

High Voltage Motors

Hyosung Heavy Industries' high voltage motors are built to comply with international standards such as KS, IEC, and NEMA. Moreover, we offer solutions that are optimized to handle specific loads based on a highly advanced insulation system.

Our motors, trusted by customers worldwide, are installed in a broad range of industries, including power generation, oil&gas, petrochemicals, desalination, shipping, and steel.

Features and Benefits

We offer specialized solutions based on superior technology.

Product Classification

Discover custom solutions that meet your needs.

IEC Standard Motor(HV)

Hyosung's IEC standard motors are built in compliance with international standards and are highly reliable due to their customization to meet individual customer requirements in both products and services. Our motors are engineered with a low-vibration and low-noise structural design, incorporating a superior insulation system, thorough process control, and quality checks. With a double squirrel-cage structure and special varnish treatment, our motors can operate seamlessly under a wide range of load conditions, including those with varying moments of inertia.

Purpose

- For pumps, fans, compressors, cranes, mills, and crushers

- For general purpose

- For petrochemical and oil&gas plants

- For cement and steel plants

- For coal-fired/combined-cycle power plants

- For nuclear power plants (Class 1E (Q-Class) & non-Class 1E electric motors)

- For ships

Scope of Production

| Output | Max. 25,000kW |

|---|---|

| Voltage | Max. 13kV |

| Number of poles | Max. 30P |

| Frequency | 50Hz, 60Hz |

| Form | TEFC, TEAAC, TEWAC, ODP, WPI, WPII, Explosion-proof |

NEMA Standard Motor(HV)

Hyosung's NEMA standard motors have been proven to meet international NEMA standards in terms of performance. Our motors are engineered with a low-vibration and low-noise structural design, incorporating a superior insulation system, thorough process control, and quality checks. With a double squirrel-cage structure and special varnish treatment, our motors can operate seamlessly under a wide range of load conditions, including those with varying moments of inertia.

Purpose

- For pumps, fans, compressors, cranes, mills, and crushers

- For general industries and steelmaking industries

- For petrochemical plants and cement plants

- For coal-fired/combined-cycle power plants

- For nuclear power plants (Class 1E (Q-Class) & non-Class 1E electric motors)

- For ships

Scope of Production

| Output | Max. 25,000kW |

|---|---|

| Voltage | Max. 13.8kV |

| Frequency | 50Hz, 60Hz |

Explosion-proof Motor(HV)

Explosion-proof motors used in the oil&gas industry must be highly durable and performance-driven, given the environments in which they are installed, where flammable gases exist. Hyosung Heavy Industries' lineup of explosion-proof motors adheres to major international standards (e.g. IECEx, ATEX, UL, CSA, GOST, KGS).

Features

| Ex d (flame-proof enclosure) |

The pressure-resistant structure of our explosion-proof motors is designed to withstand the force generated by an explosion of gases or vapors inside the container. Additionally, the motor is constructed in such a way that flammable gases or vapors from the outside cannot be ignited via joints. |

|---|---|

| Ex p (pressurized enclosure) |

To prevent explosive gases or vapors from entering the container, the motor structure pressurizes protective gas (such as air or non-flammable gas) into the container, thereby maintaining its internal pressure. |

| Ex e (increased safety) |

Our explosion-proof motor is designed with increased safety measures in terms of both its mechanical and electrical structures as well as temperature rise in order to prevent electric sparks, arcs, or high temperatures from becoming sources of ignition for flammable gases or vapors during normal operation. |

| Ex n (non-incendive) |

The structure is designed to prevent the ignition of surrounding flammable gases or vapors during normal operation. |

Scope of Production

| Pole | Max Power | Max Frame | |

|---|---|---|---|

| Ex d (flame-proof enclosure) |

~ 20P | ~ 4,000kW | ~ 800Fr. |

| Ex p (pressurized enclosure) |

~ 20P | ~ 13,000kW | ~ 1,500Fr. |

| Ex e (increased safety) |

~ 20P | ~ 13,000kW | ~ 1,500Fr. |

| Ex n (non-incendive) |

~ 20P | ~ 13,000kW | ~ 1,500Fr. |

References

Our track records speak for ourselves.

-

Saudi Arabia

Duba Combined-Cycle Power Plant (550MW)

- SEC

-

Saudi Arabia

Yanbu III Desalination Project

- SWCC

-

Kuwait

Sabiya-1 Combined-Cycle Power Plant (750MW)

- MEW

-

Kuwait

Doha RO Desalination Project

- MEW

-

Kuwait

Al-Zour Refinery Project

- KNPC

-

Qatar

Facility D IWPP Project

- Kahramaa

-

Manual

High Voltage motor instruction Manual(English)_REV 2.5

English

-

Manual

High Voltage motor instruction Manual(English)_REV 2.4

English

-

Manual

High Voltage motor instruction Manual(English)_REV 2.3

English